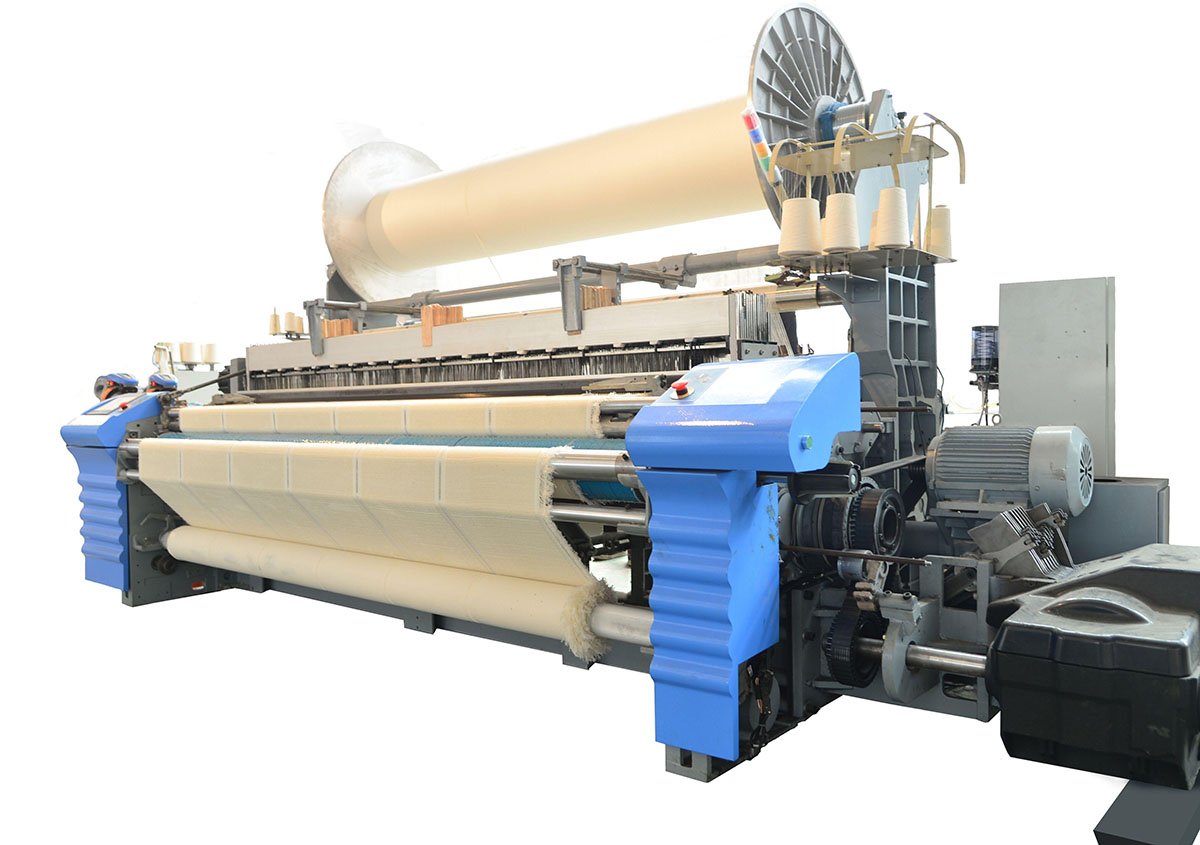

The early air jet looms had a very small scope of application, mainly producing white grey fabrics, and the fabric width was small, the speed was slow, the fabric limitations were large, and the fabric quality was not high. However, since the early 1980s, with the development of special-shaped reed and relay weft insertion technology of air-jet looms and the application of electronic computers, sensors and frequency conversion speed regulation technology, the speed of air-jet looms and the automatic monitoring of looms have been greatly improved. The level, especially the rapid development of air-jet looms in the past 10 years, has made air-jet looms have many advantages such as high quality, high speed, high output, and high level of automatic control, and the range of varieties has been greatly improved.

The width of the air jet loom has increased from 190cm, 280cm to 340cm, 360cm, 400cm or more; the main nozzle has been increased from single nozzle to double nozzle and four nozzles; the multi-color weft insertion system controlled by computer software can carry out 4 colors to 12-color weft selection; the raw materials of weft yarn can be chemical fiber filament, chemical fiber staple fiber, pure cotton yarn, wool yarn, glass fiber yarn, various fancy yarns, etc.; product varieties range from high-density, thin, high grade fabrics to coarse count and high-density fabrics Thick and thick fabrics can be produced, and DORNIER air jet looms have been used to produce industrial fabrics such as filter fabrics, emery twill fabrics, steam fabrics and fiberglass wall coverings. The new air-jet looms of Belgian Picano and Japan's Tsudakoma are also equipped with electronic jacquard, dobby and other opening systems to adapt to the production of various types of fabrics.