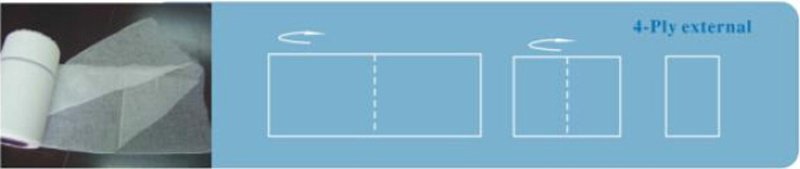

● Process flow:

90cm wide bleached gauze roll of raw materials ---- pre folded into roll by inner four fold machine ---- outer paper packaging by automatic hundred yard roll packaging machine (the first layer of white paper the second layer of blue paper the side bottom paper the side blue sealing paper)

Step 1: Prepare raw materials

Step 2: Roll up the inner four fold machine

The machine is suitable for gauze outward 4-ply folding, two operators is enough.

● Technical Parameters:

a. Max. In-feed width: 900mm, in-feeding roller core diameter: Ø75mm. The output roll diameter and fold width are as per end-users’ choice. The maximum diameter of raw material: Ø600mm, output roll core spindle diameter: 50mm or 10mm on customers’ requests.

b. Transducer power: 1.5KW

c. Air pressure: 0~0.2Mpa.

d. Speed : 10-80M/Min

● Main Features and Functions:

a. Being controlled by frequency converter, the motor drives the whole process with accurate speed regulating for stable operation. Electronic counter works precisely to set the rolled length.

b. Double spindle drive output reduces gauze hauling deformation to achieve stable folded size and the rolled-up neatness.

c. The tightness status can be regulated freely by double column pressure from rolling-up core spindle, it is clean and convenient.

d. Standardized manufacturing, main parts as frequency converter and pneumatic devices are imported brands. Protective covers are available for transmission system to achieve safety and reliability..

e. Easy operation and convenient maintenance

This process is to fold the 90cn gauze into a 22.5cm wide roll, which is 100 yards long. After the roll is completed, the diameter of the gauze roll is 15cm, the height is 22.5cm, and the length is 100 yards (90m).

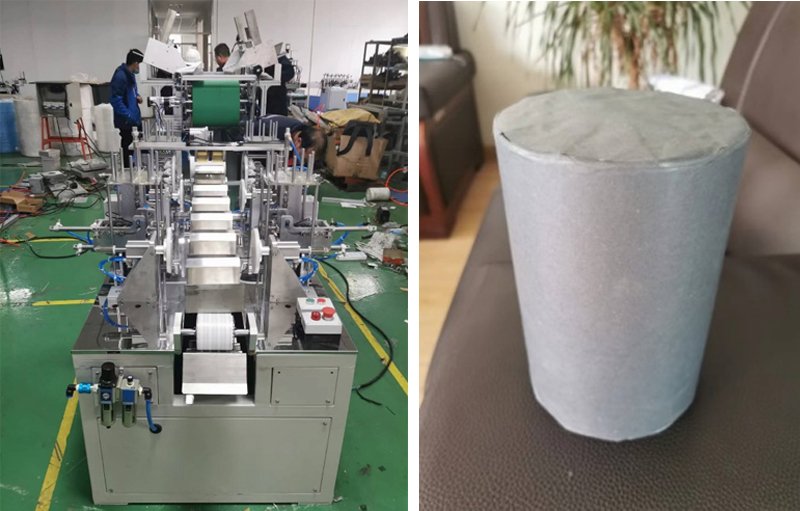

Step 3: Full automatic hundred yard roll packaging machine

JLH-BM-100

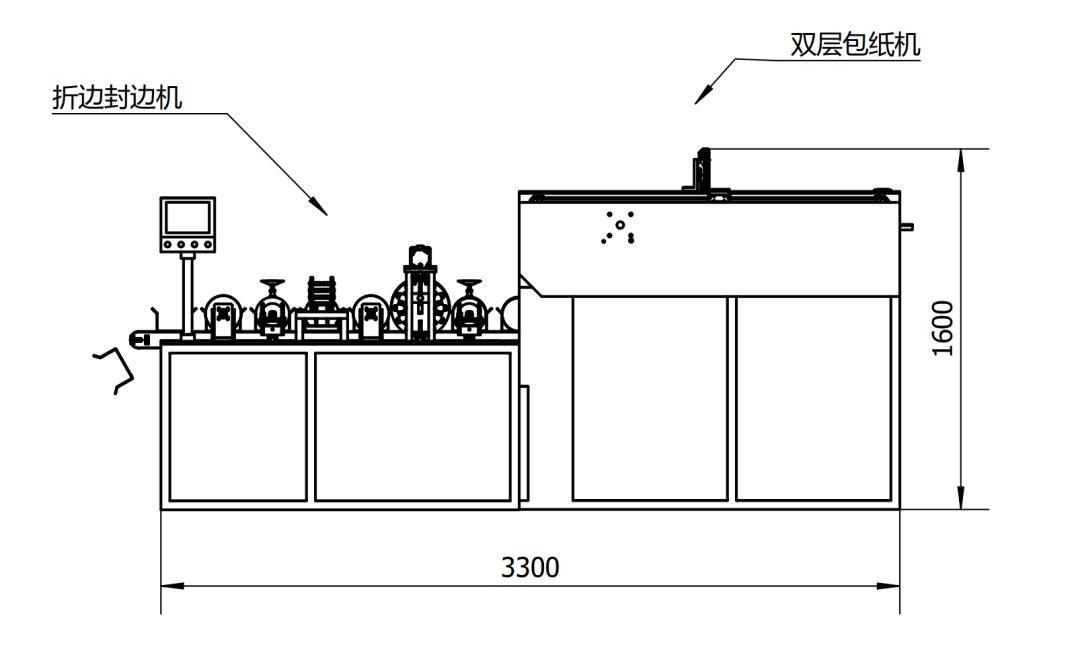

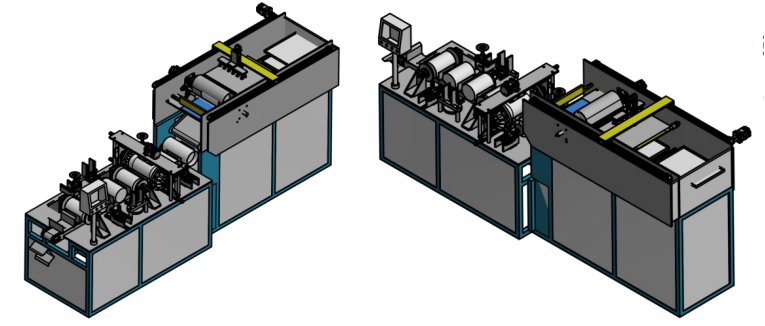

1. Mechanical structure diagram

2. Technical parameters

Total power 3.5KW

Servo motor 0.75KW/3pcs, 0.4KW/2pcs

Maximum operating speed 10PCS/MIN

Air source pressure 0.6Mpa

3. Equipment description

The inner four fold gauze packing machine adopts the independently designed mechanical structure and PLC control system, which is the first at home and abroad at present. The details are as follows:

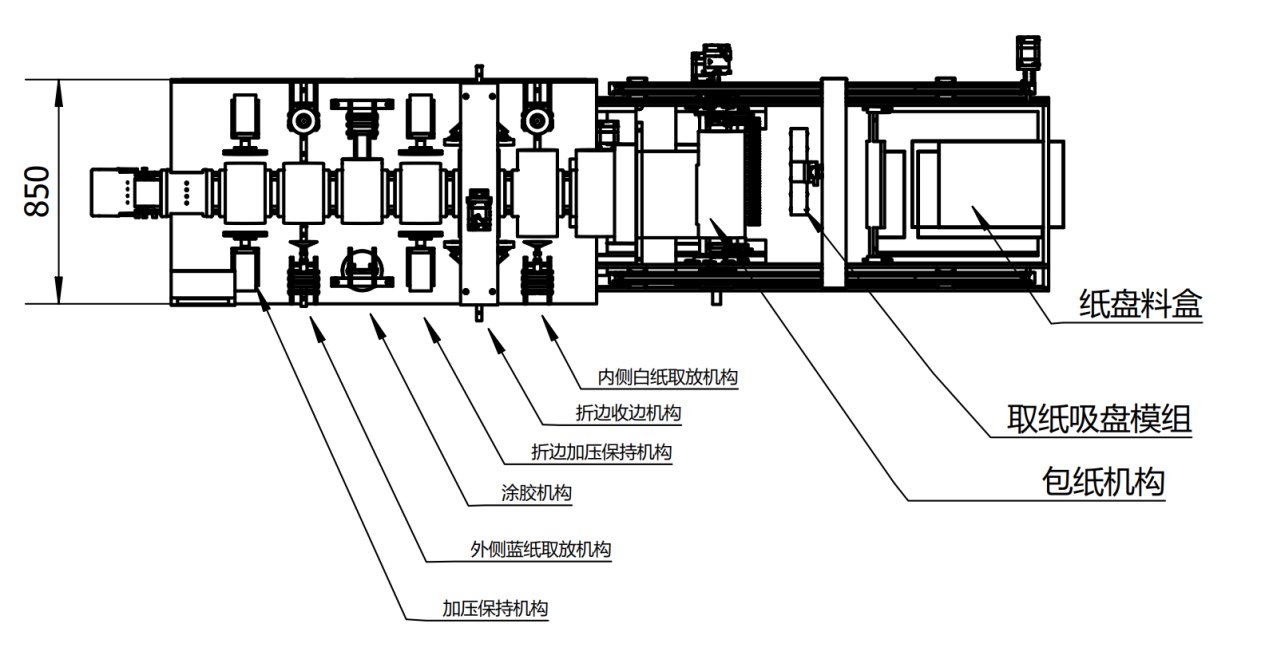

1. Double layer wrapping machine:

(1) The servo double axis linear module is used for paper picking and placing, which is stable in operation and accurate in positioning. The paper picking height is equipped with a laser distance sensor to ensure accurate paper picking due to the reduction of paper picking height in the paper tray during the operation of the equipment.

(2) The paper taking suction cup adopts vacuum negative pressure suction cup and positive pressure suction cup combined with suction cup components. When taking paper, the positive pressure suction cup actively absorbs single-layer paper, and the negative pressure suction cup is strengthened to ensure that a single sheet is taken at a time, and that the paper does not fall off and shift during transportation.

(3) The paper wrapping mechanism adopts the self-designed rotary core wound sheet base belt to drive the gauze roll to rotate and send the paper into the middle of the gauze roll and the sheet base belt through the stable paper feeding mechanism to complete the paper wrapping action. The paper wrapping of this structure is tight and the effect is good.

2. Folding and edge bonding machine:

(1) The inner white paper picking and placing mechanism adopts air cylinder to control the stroke, and the vacuum sucker completes the paper picking.

(2) The folding and edging mechanism adopts a new independently designed mechanical structure, and the cylinder controls the folding action (including initial folding and fine folding). The servo motor drives the gauze winding and folding mechanism to make a circular motion to finish the edging. The mechanical structure is ingeniously designed, which can complete the folding and edging action at one time, and the folding and edging effect is consistent with the manual effect.

(3) The folding pressure holding mechanism is used to maintain the pressure after folding through the cylinder to form a flat side for the next gluing process.

(4) The gluing mechanism adopts single action controlled by air cylinder to realize the gluing process.

(5) The outer blue paper picking and placing mechanism uses a cylinder and a real hole suction cup to complete the picking and placing action.

(6) The pressure holding mechanism is controlled by air cylinder, which makes the blue paper of the previous process tightly and smoothly attached to the side of the gauze roll.

● Overall roll folding process:

(1) Process flow of the equipment

Taking and placing white inner paper -- gauze roll placing -- feeding white inner paper into the wrapping mechanism -- gluing blue paper -- taking and placing blue paper after gluing -- feeding blue paper into the wrapping mechanism -- wrapping process is completed -- gauze roll releasing slides into the folding edger through the channel -- taking and placing white side inner paper -- folding edging -- pressure holding -- gluing -- taking and placing blue outer paper -- pressure holding -- completion

Description of equipment characteristics:

This equipment solves the problem that the original gauze roll needs manual packaging at one time. All processes and actions are automatically completed by the equipment. The packaging appearance is beautiful, the compactness is good, and the product consistency is good. It fundamentally solves the problems of insufficient compactness and inconsistent packaging caused by manual packaging.

The overall operation and action completion of the equipment are controlled by the PLC program, and the double-layer paper wrapping machine and the folding and edge banding machine are respectively controlled by two sets of independent PLC programs. The front and rear equipment can be installed and debugged separately. The equipment is easy to debug and maintain, and the operation is simple.

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.